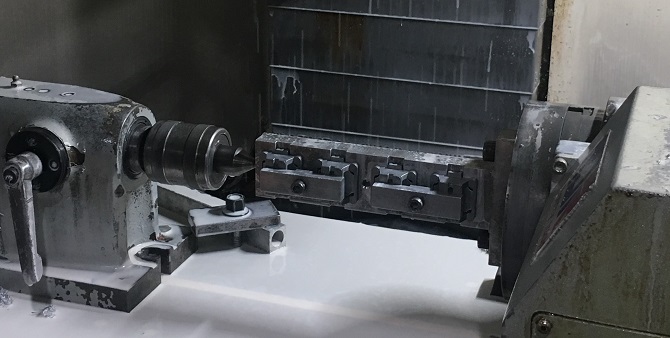

1- Workshop

2- Equipment list

SN | Equipment | Model | Processing range | Qty |

1 | NC Lathe | C6150 | Ø400*1-2M | 2 |

2 | NC Lathe (Funac system) | C6180 | Ø800*3M | 1 |

3 | Normal Lathe | C630 | Ø600*3M | 2 |

4 | Normal Lathe | C630 | Ø600*5M | 1 |

5 | Normal Lathe | C6163 | Ø630*4M | 1 |

6 | Normal Lathe | C6180 | Ø800*3M | 1 |

7 | Normal Lathe | C6180 | Ø800*5M | 1 |

8 | Normal Lathe | C666 | Ø1300*3-5M | 3 |

9 | Normal Lathe | C61140 | Ø1400*5M | 1 |

10 | Cylindrical Grinder | M131 | Ø300*1M | 1 |

11 | Internal and external cylindrical grinder | M1450 | Ø500*3.5M | 1 |

12 | Vertical CNC with Tool magazine | MDV1060E | 1000*650 | 2 |

13 | 4-axis Vertical CNC with Tool magazine | MDV1890E | 2000*900 | 1 |

14 | Horizontal boring and milling machine | DGMA3022 | 3000*2200 | 1 |

15 | Horizontal boring and milling machine (5 surface) | DGMK3525 | 3500*2500 | 1 |

16 | Auto welding machine | HD500 | 2 | |

17 | Welding machine | HXD350 | 5 | |

18 | Auto mirror polishing machine | DK500J | 2 | |

19 | High-speed balancing machine | DH500W | Ø20-1500 | 1 |

20 | CNC machine | 400*300 | 12 | |

21 | Auto Lathe | Ø1-22 | 6 |

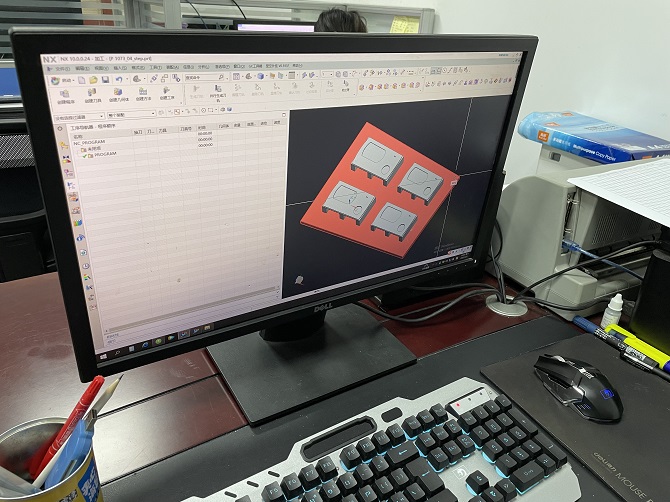

3- Production process

1- Check drawing and specification of the component;

2- Create SOP and QCS;

3- Programming;

4- Inspect manufacturing parts during production;

5- Final inspection;

6- Keep all document for tracking;

7- Make safe packing for delivery;

From the past to the present, we have produced many precision metal products, which are processed in

many ways, such like turning, milling, stamping,plastic ...... and so on. We also have assembly parts, plastic

injection parts and forging parts. In addition. We have already helped our customers with products ranging

from subsea to audio, medical and laser. With our wealth of experience and knowledge on how to machine

efficiently we can help take cost out of your design and get your projects to market faster.

Contact: Winston

Phone: 13771872249

E-mail: wst@szskyler.com

Whatsapp:Winston

Add: NO. 2, Taishan RD, SND, Suzhou, China

We chat